Empa and ETH Zurich are the researchers who compressed timber into a micro-generator and made it compressible. The electric tension is generated when it is loaded. This can be used as a bio-sensor for timber – or to generate utilizable energy. A final highlight: To ensure that aggressive chemicals are not necessary for the process, wood degradation fungi are naturally responsible for wood-modifying processes.

This was proved time to time again by Ingo Burgert and his colleagues at Empa and ETH in Zurich. Wood is so much more than just a construction material. Their study is designed to expand existing wood characteristics to suit totally new application ranges. For example, high-strength, water repellent, and magnetizable wood have already been developed. Now the team has devised a simple, environmentally friendly method for producing electricity from a kind of wood bubbler in conjunction with the Empa research team, Francis Schwarze and Javier Ribera, as reported last week in the Science Advances journal.

Contents

Voltage by distortion

The so-called piezoelectrical effect gets to play if you try to produce electricity from wood. Piezoelectricity means that the elastic deformation of solids produces an electric voltage. This phenomenon is primarily used in metrology, where sensors, for example when a mechanical load is applied, create a recharge signal.

Such sensors also use materials not appropriate for use in biomedical applications such as plum zirconate titanate (PZT), which due to the plumage it contains, cannot be used on the human skin. It also makes it very difficult to ecologically remove PZT and Co. There are thus a number of benefits to be able to use the natural piezoelectrical effect of wood. If further consideration is taken, the impact may be used to generate sustainable energy. Initially, however, the properties of wood must be provided. Wood is not versatile enough without special treatment; it can therefore only be produced by very low electrical voltage during the deformation process if subjected to mechanical stress.

Block-to-block

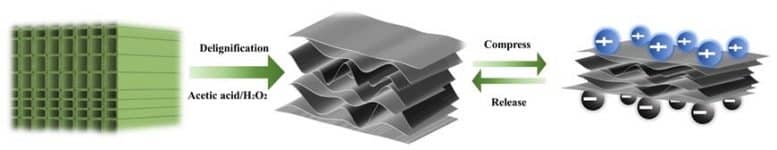

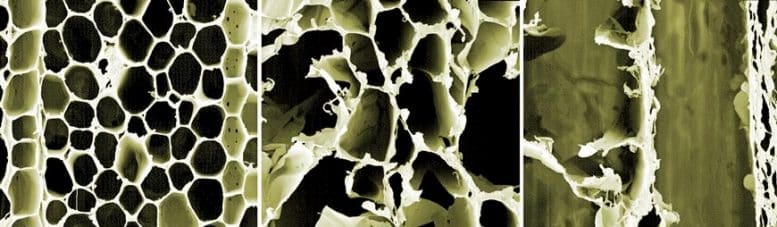

In recent years Jianguo Sun, a Ph.D. student on the Burgert team, used a chemical process that is the basis of most timber “refinements,” namely dealignment. Walls of wood cells include 3 essential materials, lignin, hemicellulose, and cellulose.

“To grow to great heights is Lignin what a tree needs mainly. With lignin, this is not possible as a stabilizing agent which connects the cells and avoids the buckling of hard cellulosic fibrils,” Burgert explains. Lignin must be at least partly ‘extracted’ in order to make wood into a substance, which can be deformed readily. The wood is put in a hydrogen peroxide mixture with acetic acid for this purpose. In this acidic bath, the lignin is dissolved and leaves a cellulose layer framework.

“We use the hierarchical structure of wood, for example, without dissolving it first, and then re-connecting the wood fibers,” says Burgert. The white wood sponge is made up of superimposed thin cellulose layers which can be pressed together and then expanded back into their original shape – wood becomes elastic.

Electricity From Wood

The team of Burgert subjected the test cube to about 600 load cycles with a side length of about 1.5cm. The material was incredibly stable. The researchers measured a voltage of around 0.63V at each compression – enough for a sensor application. The team sought to expand its wood nanogenerators in further experiments.

They have, for example, shown that 30 such wooden blocks can illuminate a basic LCD display when loaded in conjunction with the adult’s body weight. Thus, a wooden floor that can turn the energy of persons walking on it into electricity could be designed. The scientists also tested the suitability of the human skin as a pressure sensor and found that it can be used in biomedical applications.

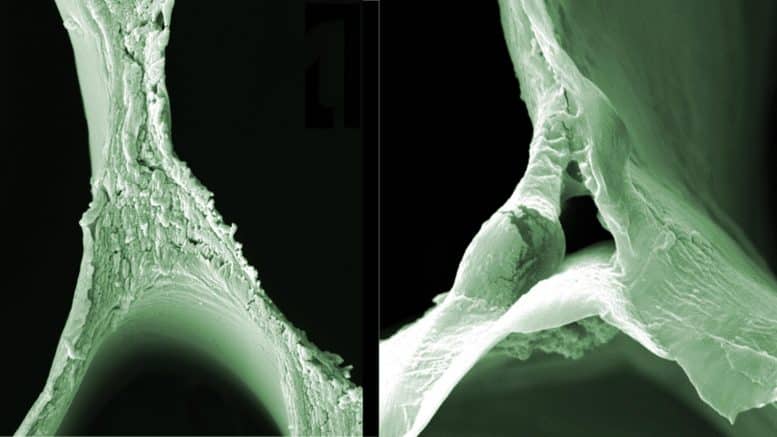

However, the work outlined in the recent publication of the Empa-ETH team takes a step further: The objective was to change the procedure so that the use of violent chemicals no longer is necessary. In a biological process in kind, the researchers discovered an appropriate candidate: Ganoderma Applanatum mushroom, causing white wood red. “The fungus breaks lignin and hemicellulose particularly softly into the wood,” explains the eco-friendly procedure, researcher Javier Ribera from Empa. Moreover, it is easy to check the process in the laboratory.

A few steps also have to be taken before the piezo can be used as an electrical sensor or as a wood floor producing electricity. But Burgert and his colleagues are currently investigating the benefits of such a basic and at the same time renewable and biodegradable piezoelectric system in a follow-up. And researchers are already in discussions with prospective cooperative partners in order to adapt the technology to industrial applications.